Heavy Duty Press for Grommets, Snaps, Buttons & Rivets (1 die set)

Our Price:

$99.99

Market Price: $129.00

Save: $29.01 per unit

Sold Out

Heavy Duty Press for Grommets, Snaps, Buttons & Rivet Package (3 die sets + 900 grommets)

Our Price:

$99.99

Sold Out

Lauren Heavy Duty Press Machine Deal

Our Price:

$84.99

Market Price: $109.99

Save: $25.00 per unit

Sold Out

Super Heavy Duty Press for Grommets, Snaps, Buttons, and Rivets (1 die set)

Our Price:

$129.99

Market Price: $299.99

Save: $170.00 per unit

Sold Out

Servo Press for Grommets, Snaps, Buttons & Rivets w/Laser Pointer (1 die set)

Our Price:

$1299.99

Market Price: $1800.00

Save: $500.01 per unit

Sold Out

Foot Press for Grommets, Snaps, Buttons, and Rivets w/Stand

Our Price:

$499.99

Market Price: $699.98

Save: $199.99 per unit

Sold Out

New Tech Pneumatic Press for Grommets, Snaps, Buttons & Rivets w/Laser Pointer (1 die set)

Our Price:

$1499.99

Sold Out

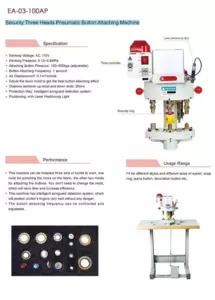

New Tech 3 Head Pneumatic Grommet Press Machine w/Laser Pointer (3 die set)

Our Price:

$2499.99

Market Price: $3600.00

Save: $1100.01 per unit

Sold Out

A grommet press is one of the tools used to attach grommets, eyelets, snaps and other accessories to fabrics, leather and other materials. Grommets are commonly used to fasten, decorate and hang items. You’ll see them in shoes, hoodies, corsets, banners, bags and various craft projects.

What is a Grommet?

A grommet is a set of two metal rings installed by pressing them together to reinforce holes on fabric or other materials so they will not unravel or wear out when a cable, string or rope goes through it. Grommets are similar to eyelets but they are usually used in heavy materials while eyelets are used in lightweight materials.

So, you’ll find grommets on flags, banners, tarps, sails or other items where heavier materials are used.

Why should you use a press to install grommets?

Grommets can also be installed using pliers, a hand press or hammer. However, if you need to continually install more than a few grommets, you’ll need a foot-operated, electronic or pneumatic grommet press for efficiency and consistent quality.

Before grommets are attached, you have to cut the holes on the fabric. However, when using a grommets press, the installation process includes cutting the hole in the fabric where the metal ring will be attached. That’s why, a grommets press is also recommended when attaching grommets to heavier materials such as leather, canvas or thick fabrics.

Imagine how tiring it will be to manually cut holes and install hundreds of grommets using pliers or a hand press. It’s also difficult to maintain consistency of location or avoid damaging the grommets.

Types of grommet presses

There are various models of grommet machines available – Hand or foot operated, electric and pneumatic.

Pneumatic grommet machines do not use electricity and do not require the physical effort of a hand-operated press.

Foot-pedal-operated machines allow the operator to install the grommets using both hands which increase productivity, improve product quality and reduce cost.

All types, from hand-operated to pneumatic models perform the complete process of hole cutting to grommet installation and are adjustable to different types of materials.

Conclusion

A grommets press makes the installation easier, faster and more accurate. While pliers may suit home sewers and crafters, commercial users need to think of productivity and efficiency. Human fatigue also increases the probability of errors and accidents. So, take a look at the various grommets models available and choose the one that best fits your needs.