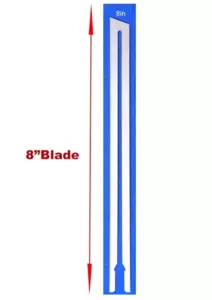

8" Blade For New-Tech Hot Cutter HS-20

Our Price:

$19.99

Market Price: $39.99

Save: $20.00 per unit

Sold Out

Hot Wire Styrofoam Foam Cutting Machine

Our Price:

$189.99

Market Price: $299.99

Save: $110.00 per unit

Sold Out

JM-817 Belt Cutter (Cold & Hot) Cutting Machine

Our Price:

$1199.99

Market Price: $1499.00

Save: $299.01 per unit

Sold Out

New Tech Electric Hot Knife Rope Cutter Bench Mount

Our Price:

$99.99

Market Price: $149.99

Save: $50.00 per unit

Sold Out

New Tech HS-68 Hotknife Cutter (110V)

Our Price:

$129.99

Market Price: $199.99

Save: $70.00 per unit

Sold Out

New Tech HS-68 Hotknife R Blade Foot Combo

Our Price:

$49.99

Market Price: $75.99

Save: $26.00 per unit

Sold Out

New Tech HS-68 Hotknife R Blade Standard

Our Price:

$19.99

Market Price: $36.00

Save: $16.01 per unit

Sold Out

New-Tech 8" Hotknife Cutter (110V)

Our Price:

$149.99

Market Price: $299.99

Save: $150.00 per unit

Sold Out

Replacement Blade for New-Tech HZ-10

Our Price:

$14.99

Market Price: $36.99

Save: $22.00 per unit

Sold Out

Hot knives, hot wire CNC machines, freehand routers and bow cutters are the most commonly used tools for cutting expanded or extruded polystyrene (EPS or XPS foam) and other synthetic materials.

Hot Knives

A hot knife uses high heat to cut and heat-seal the edges of foam. It is designed for no-dust cutting of non-pressed expanded polystyrene (EPS) and extruded polystyrene (XPS) foam and other polystyrene-based materials for industrial and commercial uses.

How a hot knife cutter works

This foam cutter has a power controller to adjust the blade temperature in seconds and needs little to no force to cut through foam easily. The hand-held model allows comfortable “free hand” cutting in a wider range of positions compared to the model with a stationary stand. Some hot knife cutters designed to cut and seal the ends of ropes, nets, and synthetic materials have computerized controls (CNC ) that can set the length of each piece as well as the quantity to cut.

Hot Wire Styrofoam Foam Cutting Machine - Hot Wire CNC machine

This is another foam cutting device that consists of a thin, taut metal wire, usually nichrome, titanium or stainless steel that is electrically heated to the specified temperature.

Hot Wire CNC (Computer Numerical Control) Foam Cutters

The hot wire CNC foam cutter is a computer- controlled machine for a fast, accurate and relatively inexpensive way of creating various products out of polystyrene-based materials. Hot wire CNC foam cutting machines have unique product software to create display letters, signboards, labels for indoor and outdoor ads, decor elements and other products made out of foam.

How hot wire CNC cutter works:

The hot wire melts through the foam along the designed cutting line, leaving a smooth edge. No need to worry about dust. Computer control makes this cutter effective in creating consistently- shaped and quality foam products.

Cutting wires

NiChrome wire is the most widely used cutting wire for both hand-held and CNC polystyrene foam cutting machines mainly because it heats up fast, it is resistant against corrosion and oxidation at very high temperatures, has high tensile strength and high melting point.

Titanium Alloy Wire is a little more expensive than the NiCr wire but it breaks less often, lasting 5-6 times longer than NiCr wire because it is much more stretch resistant at high temperatures. It is the recommended wire for machines with stronger tensioning spring or pneumatic tensioning which results to faster cutting speeds and better cutting quality.

Freehand Routers

Freehand Router has hot wire blades that can be bent into any shape for freehand sculpting and carving of large foam products. It can be compared to how a chisel is used to shape stone.

Bow Cutters

Hand held hot wire bow foam cutters are made of aluminum. Bow cutters are widely used by pros for cutting and slicing large (for example, 4x8 feet) pieces of foam and other synthetic materials for packaging or building insulation.

Which is the best foam cutter?

The most suitable foam cutter depends on the project to be cut. Each foam cutter is designed for specific purposes.